Contents

- 1 Why Latex Quality Matters in Adhesive Manufacturing

- 2 MA vs. HA Latex: What’s the Difference?

- 3 5 Powerful Reasons MA & HA Latex Are the Best for Adhesive Manufacturers

- 4 Case Study: Cutting Downtime by 17% with Latex MA

- 5 Why Procurement Teams Trust Ngoc Chau Natural Rubber

- 6 How to Choose the Best Latex for Adhesive Manufacturing

- 7 Conclusion: Don’t Settle for Unstable Latex

- 8 🔎 FAQ: Best Latex for Adhesive

In the competitive adhesive manufacturing industry, choosing the best latex for adhesive applications can make or break your product’s performance—and your profitability. As procurement officers look for stable, cost-effective, and compliant raw materials, two options often stand out: Medium Ammonia Latex (MA) and High Ammonia Latex (HA).

This article explores why Ngoc Chau’s MA and HA latex are trusted by industrial glue and bonding manufacturers across Asia, the Middle East, and beyond. Discover how the right latex improves bonding strength, enhances shelf life, and reduces operational costs.

Why Latex Quality Matters in Adhesive Manufacturing

When sourcing the best latex for adhesive, many buyers focus on price alone. However, adhesive performance depends on more than just cost:

-

Stability: Latex that separates, foams, or degrades quickly leads to rejected batches and line delays.

-

Bond Strength: Low-quality latex compromises adhesive durability and cohesion.

-

Shelf Life: Latex with poor ammonia balance or high VFA spoils faster, leading to product waste.

As a procurement officer, your challenge is to secure a latex supply that balances cost-efficiency, performance, and compliance.

MA vs. HA Latex: What’s the Difference?

Understanding the difference between MA and HA latex is crucial when selecting the best latex for adhesive:

| Latex Type | Ammonia Content | Best Use | Benefits |

| Latex MA | 0.3–0.6% (Medium) | Short-to-medium shelf life adhesives | Balanced stability with lower odor |

| Latex HA | ≥ 0.6% (High) | Long-storage or export-grade adhesives | Excellent preservation & bacterial resistance |

Ngoc Chau Natural Rubber supplies both variants, allowing adhesive manufacturers to choose based on their formulation and storage needs.

5 Powerful Reasons MA & HA Latex Are the Best for Adhesive Manufacturers

1. High Dry Rubber Content (≥ 60%)

Every liter of latex you purchase should count. Ngoc Chau’s MA and HA latex contain ≥ 60% DRC, delivering more solid material per drum and reducing per-batch latex usage.

-

📌 Procurement Benefit: Better yield and cost-efficiency

2. Superior Mechanical Stability Time (≥ 650s)

Longer MST means the latex can be mixed and processed without premature breakdown. This is essential in adhesives that involve vigorous blending or high-speed mixing.

-

📌 Production Benefit: Reduces tank cleaning and batch failure

3. Low Volatile Fatty Acid (VFA ≤ 0.06)

A major issue with inferior latex is spoilage and odor. Our low-VFA formulation prevents bacterial buildup and off-smells, maintaining latex freshness.

-

📌 Quality Benefit: Cleaner production lines, better user safety

4. Certified to International Standards (ISO & TCVN)

Our latex is certified under:

-

ISO 124:2014 – Latex composition

-

ISO 126:2005 – DRC measurement

-

TCVN 4856, 6315, 6321 – Vietnam standards for rubber quality

Each batch is shipped with full COA and MSDS.

-

📌 Compliance Benefit: Ready for export and regulatory approval

5. Flexible Packaging for Any Operation

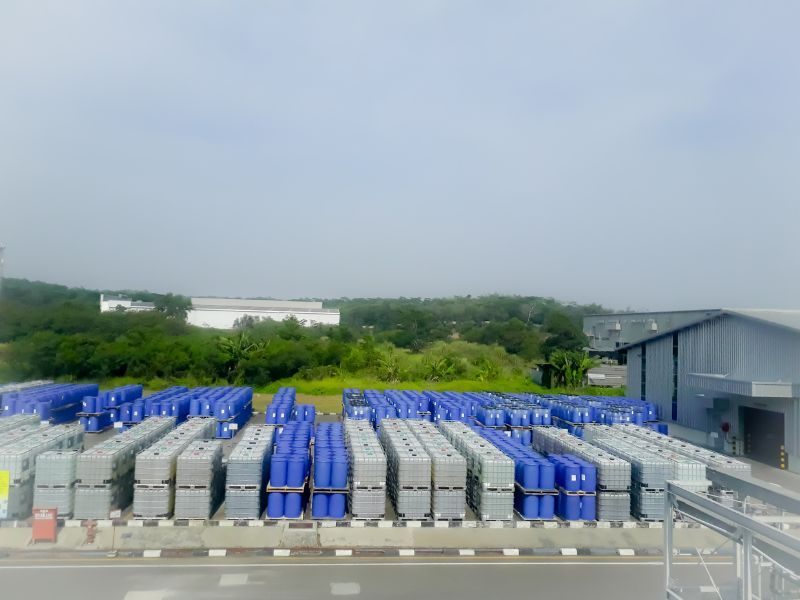

Whether you’re blending small batches or filling 20-ton tanks, Ngoc Chau can ship latex in:

-

200 kg drums

-

960 kg IBC tanks

-

25 kg jerry cans

-

20–21.5 MT flexibags

-

📌 Logistics Benefit: Custom packaging = easier inventory control and shipping

Case Study: Cutting Downtime by 17% with Latex MA

A regional adhesive factory in Australia, was facing major efficiency problems:

-

Latex batches would foam or settle during blending

-

Strong odors reduced staff satisfaction

-

QA rejected 1 in 8 adhesive drums due to instability

After switching to Ngoc Chau’s Latex MA, their results improved within 30 days:

-

✅ 17% reduction in rejected batches

-

✅ Blending time reduced by 12%

-

✅ Cleaner environment, no odor complaints

-

✅ Improved bonding strength in end-use tests

Why Procurement Teams Trust Ngoc Chau Natural Rubber

We understand that for procurement officers, reliability is everything.

That’s why Ngoc Chau offers:

-

📦 Batch-tested latex with guaranteed DRC, VFA, MST

-

🌍 Export-ready logistics with documentation support

-

🧪 Free sampling for compatibility testing

-

🛠️ Technical consulting with every shipment

Our clients span from Vietnam to Egypt, Brazil to Bangladesh—each with different adhesive formulations and operational demands.

How to Choose the Best Latex for Adhesive Manufacturing

Here’s a quick checklist when evaluating suppliers:

✅ Does the latex offer the right ammonia level for your needs?

(MA for balance, HA for long shelf life)

✅ Are MST, DRC, and VFA tested per batch?

(Get a sample COA)

✅ Are you getting export-ready packaging?

(Drums, flexibags, or IBCs)

✅ Is the supplier able to support testing or product adjustments?

(Ask for sample support)

Ngoc Chau checks all these boxes—and more.

Conclusion: Don’t Settle for Unstable Latex

If you’re searching for the best latex for adhesive, make sure you’re not compromising on performance, shelf life, or logistics.

Ngoc Chau’s MA and HA latex formulations are engineered for the demands of glue and bonding manufacturers—giving you consistent results, better bonding, and fewer production headaches.

📩 Ready to test your next batch?

✅ Request a free sample or consultation:

🌐 www.ngocchausupplier.com

📱 WhatsApp: +84 90 284 60 87

📧 Email: info@ngocchausupplier.com

🔎 FAQ: Best Latex for Adhesive

Q1: Is latex MA or HA better for adhesives?

Latex MA is suitable for general-use adhesives, while HA is ideal for long shelf life or export needs.

Q2: What certifications does Ngoc Chau’s latex meet?

ISO 124, ISO 126, TCVN 4856, and others—each batch includes COA and MSDS.

Q3: Can you provide flexible packaging?

Yes—drums, IBC, jerry cans, and flexibags based on your logistics setup.

Q4: How do I test latex compatibility with my adhesive resin?

Contact us for a free sample and run pilot tests in your blending tank.

Q5: Does Ngoc Chau offer technical advice?

Absolutely—we help clients adjust formulations, mixing ratios, and more.

Ms Evan

Ms Evan