Contents

- 1 What to Look for in Rubber for Adhesive Applications

- 2 Key Features of SVR 3L Rubber

- 3 Why SVR 3L Outperforms Other Rubber Grades for Glue

- 4 Applications Of Rubber for Adhesive in BOPP Tape & Industrial Glues

- 5 Why Global Buyers Trust Ngoc Chau’s SVR 3L

- 6 FAQs

- 7 Final Thoughts: Should You Use SVR 3L in Your Adhesive Line?

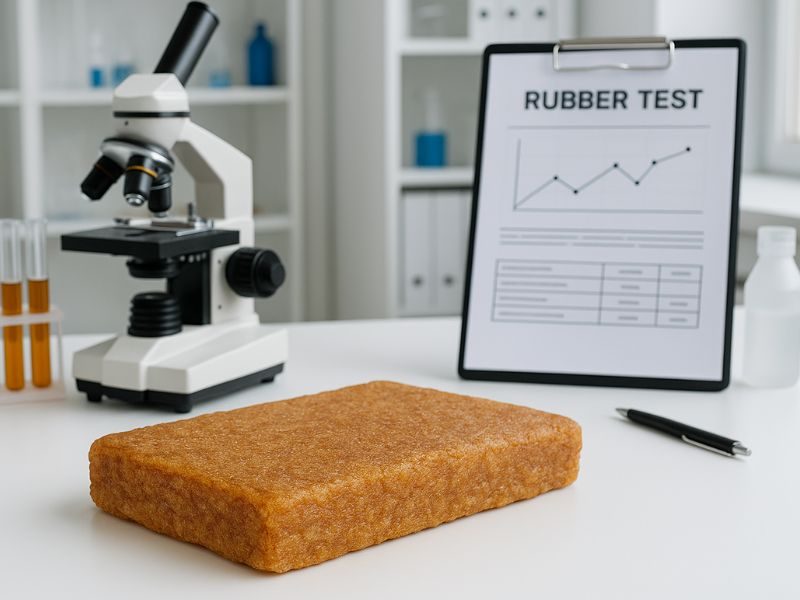

In the adhesive manufacturing world, raw material quality can make or break product performance. If you’re searching for rubber for adhesive applications that offers high purity, consistent viscosity, and strong bonding properties, SVR 3L natural rubber from Ngoc Chau stands out as a smart choice. Here’s why more factories are making the switch.

What to Look for in Rubber for Adhesive Applications

Rubber is a critical ingredient in adhesives due to its flexibility, durability, and ability to form lasting bonds with various surfaces. But not all rubber types are created equal. Manufacturers in the adhesive industry typically look for:

-

Low impurity levels: to ensure cleaner, more consistent formulation

-

Stable Mooney viscosity: for predictable flow and mixing performance

-

High plasticity retention: to maintain bonding under pressure and temperature changes

When these criteria aren’t met, manufacturers face higher rejection rates, inconsistent adhesion, and downstream customer complaints.

Key Features of SVR 3L Rubber

SVR 3L from Ngoc Chau Natural Rubber is specially engineered to meet the stringent needs of industrial applications. Here’s what sets it apart:

-

✅ Low Dirt Content (0.005%)

This high purity level ensures fewer disruptions in adhesive mixing processes and less residue in final products. -

✅ Stable Mooney Viscosity (40–50)

Helps maintain consistency across batches—ideal for automated adhesive production lines. -

✅ High Plasticity Retention Index (PRI ≥ 79)

This ensures durability and resilience in long-term adhesive bonding. -

✅ Certified to ISO & TCVN standards

Your adhesives stay compliant with international quality benchmarks.

Why SVR 3L Outperforms Other Rubber Grades for Glue

SVR 3L vs RSS 3: A Technical Comparison

| Feature | SVR 3L | RSS 3 |

|---|---|---|

| Dirt Content | ≤ 0.005% | Up to 0.1% or higher |

| Color | Bright ivory to yellow | Darker, inconsistent |

| Mooney Viscosity Stability | High | Variable |

| Plasticity Retention Index | ≥ 79 | Often < 60 |

| Processing Control | High (machine-graded) | Manual & variable |

SVR 3L’s low impurity level and consistent viscosity translate into better adhesive dispersion, stronger bonding strength, and longer product shelf life.

Applications Of Rubber for Adhesive in BOPP Tape & Industrial Glues

SVR 3L is commonly used in:

-

BOPP tape manufacturing: Offers strong adhesion on plastic surfaces while maintaining clarity and strength.

-

Shoe sole adhesive: Flexible and shock-resistant for rubber-to-fabric bonding.

-

Packaging glues: Clean bonding with minimal odor and high durability.

Case Example: Boosting Efficiency with Rubber for Adhesive Tape

A BOPP tape manufacturing plant in Brazil achieved a 12% reduction in adhesive waste after transitioning from RSS 3 to SVR 3L rubber for adhesive applications. The switch resulted in:

-

More consistent dispersion during mixing

-

Improved bonding performance across plastic substrates

-

Less downtime caused by impurities or batch variation

The plant credited SVR 3L’s stable Mooney viscosity and high-purity profile as key drivers behind these efficiency gains.

“SVR 3L helped us cut back on rejection rates and raw material loss. It’s now our go-to rubber for adhesive products.” – Production Engineer, Brazil

Why Global Buyers Trust Ngoc Chau’s SVR 3L

-

🔒 Certified Quality: Full documentation provided – COA, MSDS, TDS, C/O

-

🌍 Global Export Ready: Shipped in bale or pallet formats to over 20 countries

-

📦 Flexible Packaging: 33.33 kg / 35 kg bales; palletized shipping available

-

🧑💼 Technical Support Included: Our team helps you match specs to your adhesive system

FAQs

Q1: Is SVR 3L better than RSS 3 for adhesives?

Yes, due to lower impurity levels, more consistent viscosity, and better plasticity retention.

Q2: Can SVR 3L be used in both water-based and solvent-based adhesives?

Yes, it performs well in both systems, especially where clean dispersion and flexibility are required.

Q3: What documents are provided with SVR 3L shipments?

COA, MSDS, TDS, and Certificate of Origin (C/O) are included upon request.

Final Thoughts: Should You Use SVR 3L in Your Adhesive Line?

If you’re looking for a rubber that ensures strong, consistent bonding and meets international standards, SVR 3L from Ngoc Chau Natural Rubber is an excellent choice.

📞 Contact Us Today for a Sample or Quotation

-

WhatsApp: +84 90 284 60 87

-

🌐 Website: www.ngocchausupplier.com

-

📧 Email: info@ngocchausupplier.com

Ms Evan

Ms Evan