Contents

- 1 Why Rubber Quality is Critical in Hydraulic Hose Manufacturing

- 2 SVR 3L: The Right Rubber for Hydraulic Hoses

- 3 SVR 3L vs RSS 3: Which Rubber Performs Better for Hydraulic Hoses?

- 4 Where SVR 3L Adds Value in Hydraulic Hose Production

- 5 Case Study: How a Hose Factory Reduced Failure Rates by 18%

- 6 Why Buyers Trust SVR 3L from Ngoc Chau Natural Rubber

- 7 FAQs

- 8 Conclusion: SVR 3L as the Smart Rubber for Hydraulic Hose Applications

- 9 📩 Contact Us for Technical Consultation & Export Pricing

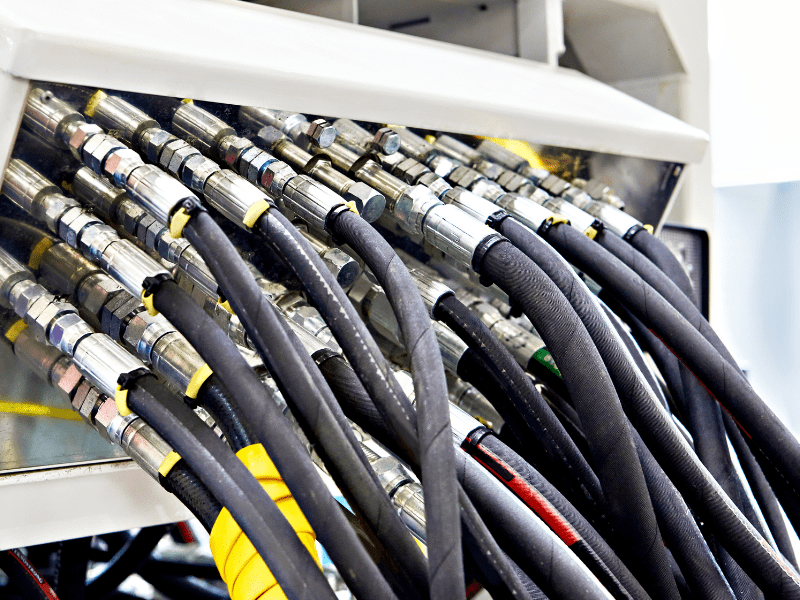

When it comes to manufacturing hydraulic hoses, few materials are more critical than rubber itself. The choice of rubber directly impacts the hose’s flexibility, durability, and ability to withstand extreme pressure. For factories seeking the optimal rubber for hydraulic hoses, SVR 3L natural rubber from Ngoc Chau Natural Rubber in Viet Nam has become a leading solution trusted by manufacturers worldwide.

Why Rubber Quality is Critical in Hydraulic Hose Manufacturing

Hydraulic hoses must endure harsh environments, frequent flexing, and extremely high internal pressure. Subpar rubber compounds can lead to:

-

Premature cracking or delamination

-

Internal defects under pressure cycles

-

Reduced elasticity and flexibility over time

-

Higher scrap rates in production

Choosing the right rubber for hydraulic hoses minimizes failure rates, improves long-term durability, and ensures reliable downstream performance in industrial, automotive, and heavy machinery applications.

SVR 3L: The Right Rubber for Hydraulic Hoses

SVR 3L Natural Rubber is a high-purity, technically specified natural rubber produced under ISO and TCVN standards. Here’s why SVR 3L excels as rubber for hydraulic hoses:

Ultra Low Dirt Content (≤ 0.005%)

-

Reduces contamination during extrusion

-

Results in smooth, defect-free inner hose walls

-

Improves long-term integrity under fluid pressure

Stable Mooney Viscosity (40–50)

-

Supports consistent flow during high-speed extrusion

-

Prevents thickness variation and weak points in hose layers

-

Minimizes variations from batch to batch

High Plasticity Retention (PRI ≥ 79)

-

Maintains flexibility even after long-term use

-

Enhances crack resistance during continuous flexing

-

Critical for multi-layered reinforced hoses

Fully Certified for Export & Industrial Compliance

-

ISO 2000:2014

-

TCVN 3769:2016

-

Backed by full export documentation (COA, MSDS, TDS, C/O)

SVR 3L vs RSS 3: Which Rubber Performs Better for Hydraulic Hoses?

SVR 3L’s higher purity and processing stability give manufacturers a stronger foundation for high-pressure hose performance and long-term reliability.

| Property | SVR 3L | RSS 3 |

| Dirt Content | ≤ 0.005% | Up to 0.1% |

| Viscosity Stability | Highly consistent | Variable batch-to-batch |

| Purity Control | Machine sorted (TSR grade) | Manual sorting |

| Flexibility Retention | Superior (PRI ≥ 79) | Less stable over time |

| Suitability for Hydraulic Hoses | Excellent | Moderate to poor |

Where SVR 3L Adds Value in Hydraulic Hose Production

SVR 3L serves multiple industries producing:

-

Hydraulic power hoses (industrial machinery)

-

Industrial pressure hoses (fluid transfer, chemical handling)

-

Automotive hoses (brake lines, steering systems)

-

Oil and gas hoses (oilfield applications)

-

Heavy equipment hydraulic systems

Its combination of flexibility, elasticity, and long-term durability makes it ideal for hose layers that must flex thousands of times without failure.

Case Study: How a Hose Factory Reduced Failure Rates by 18%

A large hydraulic hose manufacturer in Southeast Asia was facing high internal defect rates caused by contamination and inconsistent flow properties when using RSS 3. After switching to SVR 3L:

-

Failure rates in pressure testing dropped by 18%

-

Scrap waste reduced by over 10%

-

Extrusion stability improved, cutting downtime

The switch to SVR 3L resulted in more stable production, longer hose service life, and better customer satisfaction across global OEM clients.

Why Buyers Trust SVR 3L from Ngoc Chau Natural Rubber

When procurement teams and manufacturers choose Ngoc Chau as their supplier for SVR 3L, they benefit from:

-

📦 Full packaging flexibility for container shipments (bales/pallets)

-

📄 Full export documentation (COA, MSDS, TDS, C/O)

-

🌍 Export capacity to 20+ countries

-

🔧 Technical support for material optimization

-

🚀 Stable and scalable supply for both trial and bulk orders

FAQs

Q1: Is SVR 3L suitable for high-pressure hydraulic hoses?

Yes — its purity, stability, and flexibility retention make it ideal for both industrial and automotive hose applications.

Q2: How does Mooney viscosity stability improve hose production?

It allows extrusion machines to run at consistent speeds, reducing dimensional defects and wall thickness variation.

Q3: Can switching to SVR 3L reduce manufacturing scrap?

Absolutely. Clean material with stable flow properties reduces defect rates and cuts waste at every stage of production.

Conclusion: SVR 3L as the Smart Rubber for Hydraulic Hose Applications

SVR 3L natural rubber offers:

-

🔧 Stable production

-

⚙ Long-lasting flexibility

-

📄 Export certifications

-

🚢 Global delivery capability

-

💡 Reduced scrap and better extrusion stability

For manufacturers seeking the best rubber for hydraulic hoses, SVR 3L offers unmatched value.

📩 Contact Us for Technical Consultation & Export Pricing

📞 WhatsApp: +84 90 284 60 87

🌐 Website: www.ngocchausupplier.com

✉ Email: info@ngocchausupplier.com

Ms Evan

Ms Evan