Contents

- 1 Why Glove Manufacturers Face Consistent Coating and Quality Issues

- 2 What Is Latex HA and Why Is It Ideal for Glove Production?

- 3 5 Benefits of Ngoc Chau Latex HA for Glove Production

- 4 Case Study: How One Factory in Indonesia Reduced Rejections by 38% Using Ngoc Chau Latex HA

- 5 Why Glove Factory Managers Prefer Ngoc Chau Natural Rubber

- 6 How to Evaluate a Latex Supplier for Gloves

- 7 Conclusion: Quality Gloves Start with Quality Latex

- 8 FAQ: Latex for Gloves

Glove manufacturing is a precision-driven process. From mold dipping to drying and demolding, each step must operate smoothly to ensure high yield and product quality. Yet, even the most advanced production lines can be held back by one weak link: unstable or substandard latex for gloves.

For factories aiming to reduce coating defects, boost uptime, and meet international quality standards, the solution begins with the right latex. And for many glove factories across Iran, Egypt, Turkey, Russia, Uzbekistan, and even the Americas, that means Ngoc Chau’s Latex HA — a high ammonia latex engineered for consistency, hygiene, and high-speed production.

Why Glove Manufacturers Face Consistent Coating and Quality Issues

Even in well-maintained facilities, glove production issues are common. These include:

- Peeling or delamination of the latex film after curing

- Pinholes, microbubbles, or irregular glove thickness

- Frequent tank cleaning due to foaming or unstable viscosity

- Strong odor complaints from high VOC or bacterial contamination

- High rejection rates, increasing raw material waste

In many cases, these problems are caused not by machinery or labor, but by poor latex quality — specifically, latex that lacks stability, is easily contaminated, or doesn’t hold up during continuous dipping.

What Is Latex HA and Why Is It Ideal for Glove Production?

To choose the right latex for gloves, you need to understand Latex HA stands for High Ammonia Latex, containing ≥0.6% ammonia to preserve latex stability, prevent microbial growth, and enhance storage life.

For glove manufacturing, Latex HA offers critical advantages:

- Bacterial resistance – no need for additional preservatives

- Longer tank life – latex stays usable over multiple production shifts

- Smooth film formation – reduced defects in glove coating

- Lower rejection rates – fewer pinholes or surface flaws

- Consistent viscosity – reliable dipping line performance

In short, Latex HA helps ensure that every glove meets performance, safety, and compliance expectations.

5 Benefits of Ngoc Chau Latex HA for Glove Production

At Ngoc Chau Natural Rubber, we supply premium High Ammonia Latex (HA) specifically engineered for glove production lines. Here’s what sets our latex apart:

| Feature | Specification & Benefit |

|---|---|

| High Dry Rubber Content | DRC ≥ 60.2% – Increases yield per kg, results in stronger, more elastic gloves |

| Superior Mechanical Stability | MST ≥ 650 seconds – Maintains latex stability during continuous dipping and agitation |

| Ultra-Low Volatile Fatty Acid | VFA ≤ 0.06 – Prevents bacterial odor and degradation, ensuring longer shelf life |

| International Certifications | Complies with ISO 2004:2024 and TCVN 6314:2013 – Meets global glove production standards |

| Flexible Packaging Options | Drums (200 kg), IBC tanks (960 kg), flexibags, jerry cans – Export-ready, tailored to need |

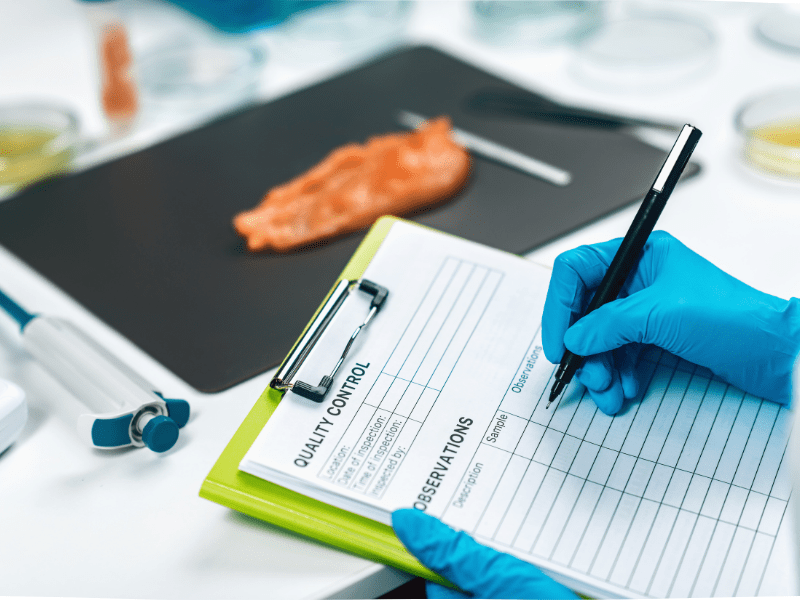

Case Study: How One Factory in Indonesia Reduced Rejections by 38% Using Ngoc Chau Latex HA

A household glove factory in Indonesia had long struggled with rising rejection rates and production inefficiencies. Key issues reported by their QA and production teams included:

- Frequent pinholes and poor coating adhesion

- Over 12% rejection rate during QA inspections

- Strong ammonia odor affecting downstream operations

After switching to Ngoc Chau’s High Ammonia Latex (HA), the factory saw rapid improvements:

- Rejection rate dropped by 38% within just two months

- Dipping tanks became more stable, requiring less frequent adjustments

- Noticeable reduction in ammonia odor, improving air quality on the floor

- Smoother mold-release and fewer delays across shifts

“Ngoc Chau’s latex brought immediate improvements. We didn’t realize how much our old latex was holding us back.”

— Production Supervisor, Glove Factory, Indonesia

Why Glove Factory Managers Prefer Ngoc Chau Natural Rubber

Beyond high product quality, Ngoc Chau is known for responsive service and export-ready operations:

- 📄 Batch COA and MSDS provided with every shipment

- 📦 Custom packaging for different line capacities

- 🌍 Fast logistics and bilingual customer support

- 🛠️ Technical consulting available for process optimization

We’ve supported factories across Iran, Egypt, Turkey, Russia, Uzbekistan, and even the Americas — from medical glove manufacturers to household glove producers.

How to Evaluate a Latex Supplier for Gloves

Before choosing a latex supplier, glove manufacturers should ask:

- Do they offer Latex HA with ≥0.6% ammonia?

- Are MST, DRC, and VFA values tested and documented?

- Is the latex certified under ISO and/or TCVN standards?

- Can they provide packaging suitable for your line size and storage?

- Do they allow sample testing before full purchase?

Ngoc Chau confidently answers “yes” to every question — and our clients see the difference in their glove quality and yield.

Conclusion: Quality Gloves Start with Quality Latex

Glove manufacturing depends on precision, but the outcome is only as strong as your raw material. With Ngoc Chau Latex HA, you gain:

- Better coating performance

- Lower defect rates

- Cleaner factory environments

- Compliance with global standards

If you’re sourcing latex for gloves, Ngoc Chau’s latex HA offers proven stability to minimize downtime, enhance glove quality, and ensure compliance with international hygiene standards — making it the smart upgrade your production line needs.

📩Request a Free Sample – Cut Defects by Up to 38%

Experience the performance of Ngoc Chau Latex HA on your production line — risk-free.

Our experts are here to support your testing, provide tailored advice, and help you boost QA results.

📞 WhatsApp: +84 90 284 60 87

🌐 Website: www.ngocchausupplier.com

✉️ Email: info@ngocchausupplier.com

FAQ: Latex for Gloves

Q1: What kind of latex is used for glove production?

High-ammonia latex (HA) is used for its antibacterial properties and stability during dipping.

Q2: Can Latex HA reduce glove defects?

Yes. It improves coating consistency and reduces peeling, pinholes, and mold-related flaws.

Q3: What’s the difference between Latex HA and MA?

HA contains more ammonia (≥0.6%) for better preservation; MA has lower ammonia but shorter tank life.

Q4: Is Ngoc Chau’s Latex HA certified?

Yes. It meets ISO 2004:2024 and Vietnamese Standard TCVN 6314:2013

Q5: Can I test the latex before ordering in bulk?

Absolutely. Free samples are available for dipping trials and QA evaluation.

Ms Evan

Ms Evan