Contents

- 1 Product introduction SVR CV50

- 2 Outstanding main features of SVR CV50 rubber

- 3 SVR CV50 Packaging – International Standard Export Solution

- 4 Discover the detailed specifications of SVR CV50

- 5 Important applications of SVR CV50 rubber in industry

- 6 The Process of Harvesting and Manufacturing SVR CV50 Rubber

- 7 Exploring the leading supplier of SVR CV50 rubber?

- 8 FAQ – SVR CV50 – Quick answers for buyers

- 9 Conclusion

SVR CV50 is a premium grade of Vietnamese natural rubber, recognized for its constant viscosity, high elasticity, and durability. It is widely applied in tire manufacturing, footwear, rubber goods, and technical products where stability is essential. Produced under strict quality control and international standards, Ngoc Chau Supplier provides SVR CV 50 as a reliable, cost-effective raw material trusted by manufacturers worldwide.

Product introduction SVR CV50

SVR CV50 is a type of block natural rubber from Vietnam, manufactured in compliance with both national (TCVN) and international standards. Its distinctive feature lies in the designation CV – Constant Viscosity, which means that the Mooney viscosity is carefully regulated throughout the production process.

The number 50 indicates the average viscosity level (50 ± 5 MU), ensuring consistency across batches and minimizing quality fluctuations. Thanks to this characteristic, SVR CV50 is widely recognized as a natural rubber grade ideally suited for industries that require high stability in processing and compounding.

Outstanding main features of SVR CV50 rubber

SVR CV50 is among the most sought-after grades of natural rubber, renowned for its stability, ease of processing, and superior durability. With its outstanding technical characteristics, this material meets the demanding requirements of multiple industries, particularly in premium tire manufacturing, technical rubber components, and high-performance rubber compounds.

Stable Viscosity – Consistent Quality

SVR CV50 is manufactured with a Mooney viscosity consistently maintained at 50 ± 5 MU, ensuring uniform quality across every batch. Its stable viscosity allows for easier processing, minimizes risks during compounding, and enables manufacturers to maintain precise control over production. This is a key advantage for businesses seeking a reliable raw material with predictable performance and long-term stability.

Flexibility – Energy Saving Processing

SVR CV50 features a naturally flexible structure that reduces energy consumption during milling. The rubber blends seamlessly with additives, producing a uniform compound and stronger bonding between components. As a result, manufacturers can enhance productivity, lower production costs, and streamline operational time.

Mechanical Strength – Superior Elasticity

SVR C V 50 is distinguished by its exceptional tensile strength and remarkable elasticity, ensuring end products with outstanding durability, flexibility, and load-bearing capacity. These superior mechanical qualities make it the material of choice for demanding applications, particularly in the manufacture of heavy-duty truck tires, sealing gaskets, power transmission belts, and a wide range of industrial components requiring long-term reliability.

Wear Resistance – Heat Tolerance

Another outstanding advantage of SVR CV50 lies in its wear resistance, heat resistance and aging resistance. Even under high pressure, constant friction or extreme temperatures, the rubber retains stable mechanical properties. This ensures long-term performance, making it a reliable choice for industries that require durability and stability.

High Purity – Uniform Performance

SVR CV50 is produced through a rigorously controlled process that minimizes impurities and maintains exceptionally low ash content. The outcome is a rubber grade distinguished by its brighter appearance, superior purity, and remarkable uniformity. Such consistency enables manufacturers to reduce production defects, achieve greater operational reliability, and deliver end products of consistently higher quality.

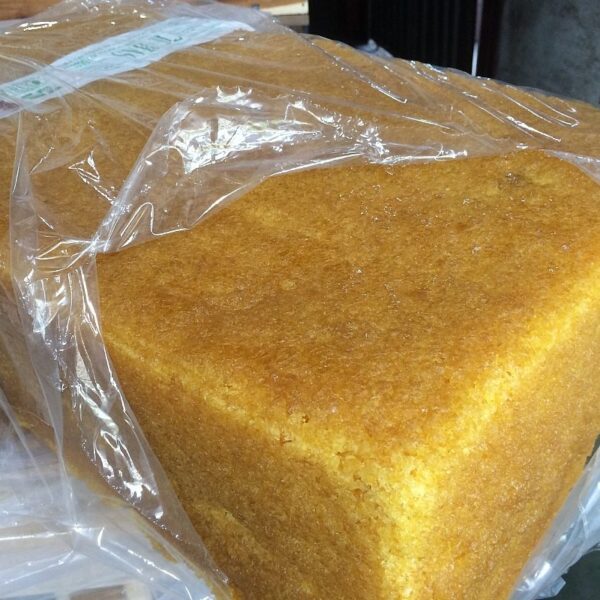

SVR CV50 Packaging – International Standard Export Solution

To comply with global preservation and logistics requirements, SVR 20, SVR CV50 is packed with strict quality control, guaranteeing hygiene, safety, and ease of handling. Each unit is pressed into 33.33 kg or 35 kg bales, carefully sealed in PE film, and loaded into 20-foot containers for secure international shipment.

BALE Packing:

| Quantity per Unit | Total Units | Container Type | Total Weight (MTs) |

| 33.33 kg / Bale | 600 – 630 bales | 20’ DC | 20 – 21 MTs |

| 35 kg / Bale | 600 – 630 bales | 20’ DC | 21 – 22.05 MTs |

PALLET Packing:

| Quantity per Unit | Total Units | Container Type | Total Weight (MTs) |

| 33.33 kg / Bale; 36 Bales / 1.20 MT / Pallet | 16 pallets | 20’ DC | 19.20 MTs |

| 35 kg / Bale; 36 Bales / 1.26 MT / Pallet | 16 pallets | 20’ DC | 20.16 MTs |

Discover the detailed specifications of SVR CV50

S V R C V 50 is manufactured under strict quality control to ensure uniformity, purity and long-term performance. The following are the main specifications, test results and international standards applied:

| Property | Test Result | Specification Limit | Test Method |

| Dirt content retained on sieve (% by weight) | 0.005 | ≤ 0.03 | TCVN 6089:2016 (ISO 249:2016) |

| Ash content (% by weight) | 0.20 | ≤ 0.50 | TCVN 6087:2010 (ISO 247-1:2018) |

| Volatile matter content (% by weight) | 0.19 | ≤ 0.80 | TCVN 6088-1:2014 (ISO 248-1:2018) |

| Nitrogen content (% by weight) | 0.43 | ≤ 0.60 | TCVN 6091:2016 (ISO 1656:2019) |

| Initial Wallace Plasticity (P₀) | 40.1 | ≥ 35 | TCVN 8493:2010 (ISO 2007:2018) |

| Plasticity Retention Index (PRI) | 79 | ≥ 60 | TCVN 8494:2020 (ISO 2930:2017) |

| Lovibond color index | 4.3 | ≤ 6 | TCVN 6093:2013 (ISO 4660:2011) |

✅ All quality assessments follow TCVN 3769:2016, consistent with ISO 2000:2014.

Important applications of SVR CV50 rubber in industry

With outstanding features, SVR CV 50 provides optimal solutions for many diverse applications.

Heavy duty truck tires

SVR CV50 is widely used in the production of truck and bus tires, where exceptional load-bearing capacity and long-term durability are essential. With its stable viscosity and high tensile strength, this grade of rubber enhances road grip while reducing wear and cracking under continuous operation. As a result, transportation companies can lower replacement costs, improve safety, and maximize the efficiency of their fleets.

Aircraft tires

In the aviation industry, aircraft tires are subjected to extreme temperatures, intense friction, and immense pressure during every takeoff and landing. With its exceptional stability and flexible elasticity, SVR CV50 fully meets these demanding requirements. This grade of natural rubber provides outstanding resistance to deformation, preserves structural integrity, and ensures consistent mechanical strength, even under the harshest operating conditions.

Industrial conveyor belt

Conveyor systems in mining, cement production, and metallurgy often operate in highly abrasive environments. SVR CV50 is an ideal material for manufacturing conveyor belts thanks to its excellent resistance to wear, tearing, and long-term mechanical degradation. This ensures continuous operation, minimizes downtime, and significantly reduces maintenance costs.

Elastic bands & stretchable goods

With its natural flexibility and elasticity, it is an ideal material for producing rubber bands, elastic threads, and fastening ties. These products require stable stretchability and resistance to brittleness over time, making SVR CV50 a sustainable solution for durable household applications.

Adhesive products

SVR CV50 blends effectively with additives, making it highly suitable for the production of adhesives and bonding agents. This property enhances adhesion, improves bond quality, and streamlines manufacturing processes. As a result, it is widely applied across various industries, including woodworking, textiles, construction, and packaging.

The Process of Harvesting and Manufacturing SVR CV50 Rubber

SVR CV50 is produced through a modern, tightly controlled process that ensures consistent quality and full compliance with international standards. The key stages of production are outlined below:

- Harvesting Latex → Collect fresh latex from Hevea brasiliensis trees.

- Coagulation & Preliminary Processing → Use formic acid to coagulate, then cut into small pieces and wash thoroughly to remove impurities.

- Milling & Drying → Sheet the rubber, then dry at controlled temperatures to eliminate excess moisture.

- Viscosity Stabilization (CV Treatment) → Adjust and maintain Mooney Viscosity consistently at 50 ± 5.

- Quality Control → Test ash, nitrogen, volatile matter, PRI, and tensile properties in accordance with TCVN/ISO standards.

- Packaging → Compress into 33.33 kg or 35 kg bales, wrap in PE film, and load on pallets or directly into 20’ DC containers.

Exploring the leading supplier of SVR CV50 rubber?

Ngoc Chau Natural Rubber Factory is a reliable partner in supplying premium S V R CV50, backed by years of expertise and proven industry excellence. Here’s what sets us apart:

- Cutting-Edge Technology: Modern production lines and advanced machinery guarantee consistent quality and stable performance in every batch of SVR CV50.

- Commitment to Sustainability: Our eco-conscious operations minimize waste and emissions, ensuring compliance with global environmental standards.

- Trusted Worldwide: We proudly serve customers across the USA, Europe, India, Korea, Malaysia, and beyond, delivering reliability and long-term value.

- Tailored Solutions: From flexible packaging options to optimized logistics, we adapt to customer needs and ensure efficient, on-time delivery.

FAQ – SVR CV50 – Quick answers for buyers

Is SVR CV50 resistant to wear and heat?

Yes. With a PRI of 79 (≥ 60) and stable mechanical properties, SVR CV50 retains strength and elasticity under continuous friction and high temperatures, making it ideal for heavy-duty industrial use.

Standards & documentation?

Inspections are carried out in accordance with TCVN/ISO standards (as shown in the table above). A Certificate of Analysis (COA) is provided for each batch, and an MSDS is available upon request. Packaging and labeling are carried out in compliance with international export requirements.

Storage & recommended shelf life?

Store in a cool, dry place, away from direct sunlight and exposure to ozone, store on pallets according to the FIFO principle. Shelf life depends on storage conditions; recommended to use as soon as possible.

What are the main technical specifications of SVR CV50?

Typical values include dirt 0.005% (≤ 0.03), ash 0.20% (≤ 0.50), volatile matter 0.19% (≤ 0.80), nitrogen 0.43% (≤ 0.60), P₀ 40.1 (≥ 35), PRI 79 (≥ 60), and Lovibond color index 4.3 (≤ 6).

Conclusion

Recognized for its stability, durability and flexibility, this SVR CV50 rubber delivers reliable performance across a wide range of industries – from heavy-duty truck tires to adhesives and elastomers. Manufactured under strict quality control and in compliance with international standards, Ngoc Chau Natural Rubber ensures consistent quality in every batch, while providing sustainable operations and a reliable global supply chain for long-term success.

Contact Ngoc Chau Natural Rubber at Lexington Building, Ho Chi Minh City – Hotline: +84 76 279 8888 | Email: info@ngocchausupplier.com for inquiries, quotations, and partnership opportunities.

Ms Evan

Ms Evan