Contents

- 1 What Is SVR 3L Natural Rubber?

- 2 Key Characteristics of SVR 3L / TSR 3L Natural Rubber

- 3 Overview assessment of SVR 3L technical specifications

- 4 SVR 3L / TSR 3L Production Process by a Vietnam Supplier

- 5 Standardized packing process of SVR 3L natural rubber

- 6 Applications of rubber natural SVR 3L products

- 7 Why Source SVR 3L from a Vietnam Manufacturer and Supplier Like Ngoc Chau Natural Rubber?

- 8 FAQ – Rubber SVR 3L product related questions

- 9 Conclusion

SVR 3L (also known as TSR 3L) is a premium technically specified natural rubber (TSR) grade known for its light color, low dirt content, and stable processing performance. It is widely used by manufacturers worldwide in tire, industrial, and technical rubber production where consistent quality is essential, as even small raw-material variations can lead to higher rejection rates and hidden costs.

Vietnam has become a major global source of technically specified rubber thanks to its strong plantation base and processing expertise, and is increasingly recognized as a reliable sourcing origin. As a Vietnam-based SVR 3L manufacturer and supplier, Ngoc Chau Natural Rubber supplies international buyers who prioritize stable quality, technical reliability, and professional export support, including buyers who reference TSR 3L in international trade.

What Is SVR 3L Natural Rubber?

SVR 3L (also known as TSR 3L) is a premium Vietnamese natural rubber grade valued for its light color, low dirt content, and low volatile matter. It is widely selected by manufacturers who require high purity, consistent processing, and reliable mechanical performance in demanding applications such as premium tires, belts, hoses, and technical industrial goods.

It is commonly sourced from Vietnam manufacturers and suppliers by international buyers seeking technically specified rubber with consistent quality. In international markets, this grade is frequently traded under the term TSR 3L rubber in procurement documents and technical specifications.

Produced from selected natural latex and field coagulum, SVR 3L undergoes controlled cleaning, shredding, washing, drying, and baling processes to ensure stable quality. The grade complies with strict international specifications (ISO/TCVN) for dirt, ash, nitrogen, and volatile content, helping manufacturers achieve predictable performance and reduced production defects.

TSR 3L is the international terminology for technically specified rubber meeting equivalent quality parameters to SVR 3L.

What Does “3L” Mean in SVR 3L?

-

Light color

-

Low dirt content

-

Low volatile matter (low volatiles)

This designation indicates a clean, high-purity rubber suitable for technical and high-performance rubber products.

Key Characteristics of SVR 3L / TSR 3L Natural Rubber

1. Purity & Appearance

Purity & Appearance: Very low dirt (≤0.03%), low ash (≤0.50%), and low volatile matter (≤0.80%) ensure a clean, high-purity rubber with a bright light-yellow color, suitable for light-colored and export-grade rubber products while helping manufacturers reduce contamination risks.

Key Indicators:

-

Dirt ≤0.03% for cleaner processing

-

Ash ≤0.50% for controlled mineral residue

-

Volatile matter ≤0.80% for stable quality

-

Bright light-yellow appearance for premium products

2. Processing Stability

Processing Stability: Stable Mooney viscosity supports consistent mixing, shaping, and curing, allowing manufacturers to maintain predictable processing and minimize material waste.

Key Indicators:

-

Stable Mooney viscosity for consistent processing

-

Predictable mixing and molding behavior

-

Reduced material waste in production

-

Mild, natural latex odor typical of clean natural rubber

3. Mechanical Strength

Mechanical Strength: As a high-purity technically specified rubber, SVR 3L provides strong elasticity, tensile strength, and abrasion resistance for durable, high-performance applications.

Key Indicators:

-

High elasticity for flexible products

-

Strong tensile strength for demanding uses

-

Good durability in industrial applications

-

Reliable abrasion resistance

4. Consistency

Consistency: Uniform batch-to-batch quality ensures reliable physical properties and stable performance in standardized manufacturing.

Key Indicators:

-

Batch-to-batch uniformity

-

Reliable physical properties

-

Suitable for continuous industrial production

-

Supports quality consistency in finished goods

Overview assessment of SVR 3L technical specifications

Below is a typical technical specification overview of SVR 3L natural rubber. Values may vary slightly by production batch.

- Dirt Content: Not more than 0.03% (retained on a 45µm sieve).

- Ash Content: Not more than 0.50%.

- Nitrogen Content: Not more than 0.60%.

- Volatile Matter: Not more than 0.80%.

- Initial Plasticity (Po): Not less than 35.

- Plasticity Retention Index (PRI): Not less than 60.

- Mooney Viscosity (ML 1’+4′ at 100°C): Typically ranges from 65–85, indicating stable processing.

- Color: Light, bright yellow, with a Lovibond index typically not exceeding 6 for single color.

SVR 3L / TSR 3L Production Process by a Vietnam Supplier

SVR 3L (TSR 3L) is produced through a controlled, step-by-step process designed to ensure clean, consistent, and technically specified natural rubber. At Ngoc Chau Natural Rubber, production is managed at Vietnam processing facilities under TCVN-compliant quality systems.

Step-by-Step Production Process

1. Latex Collection & Preservation

Fresh latex from Hevea brasiliensis trees is carefully collected. Preservatives such as ammonia or sodium sulfite are added to prevent premature coagulation during transport to the processing facility.

2. Coagulation

Formic acid is introduced to the preserved latex, allowing the rubber to separate from the serum and form solid coagulum.

3. Milling & Shredding

The coagulated rubber is processed through crepers and shredders to remove excess water and convert it into small, manageable crumbs.

4. Washing

Rubber crumbs are thoroughly washed to reduce dirt and non-rubber components, supporting higher cleanliness levels.

5. Drying

Clean crumbs are dried under controlled conditions to achieve the required moisture content and stable quality parameters.

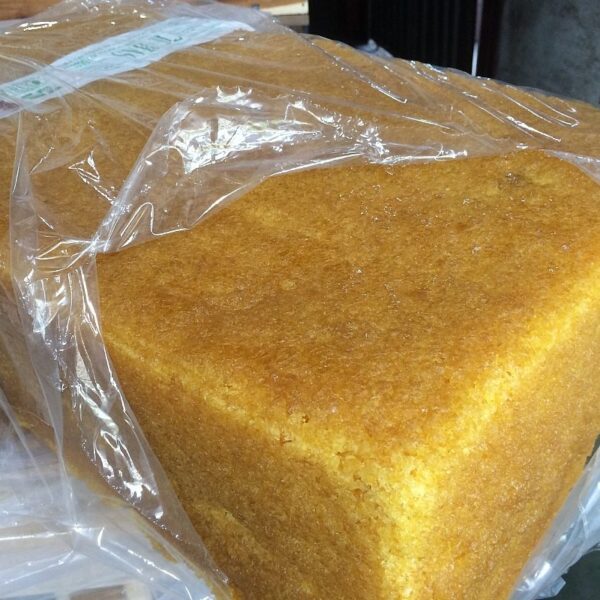

6. Baling & Packaging

The dried rubber is pressed into uniform bales, wrapped in polyethylene film, and prepared for export shipment to international buyers.

As a Vietnam manufacturer and supplier, Ngoc Chau maintains process control to support consistent export-grade quality.

Standardized packing process of SVR 3L natural rubber

Ngoc Chau Natural Rubber supplies SVR 3L with export-standard packaging compliant with ISO/TCVN specifications. Packaging solutions are designed to support international buyers sourcing from Vietnam manufacturers and suppliers.

Benefits of Ngoc Chau’s Packing Options

-

33.33 kg vs 35 kg bale options

→ Flexible for different mixing lines and batch formulations; 33.33 kg fits traditional loading patterns, while 35 kg maximizes payload for cost efficiency. -

Palletized loading

→ Faster loading/unloading, reduced bale deformation, safer storage, and lower labor intensity at receiving factories. -

Optimized weight per 20ft container

→ Ensures stable loading, minimal cargo shift, and maximum usable weight within ocean freight regulations. -

Export-ready documentation

→ COA per batch, pallet labels, bale numbering, fumigation certificates (when required).

| Packaging Type | Quantity per Unit | Total Units | Total Weight (MTs) | Container Type |

| BALE | 33.33 kgs/Bale | 600 – 630 bales | 20 – 21 MTs | 20 DC |

| 35 kgs/Bale | 600 – 630 bales | 21 – 22.05 MTs | 20 DC | |

| PALLET | 33.33 kgs/Bale; 36 Bales/1.2 MTs/Pallet | 16 pallets | 19.2 MTs | 20 DC |

| 35 kgs/Bale; 36 Bales/1.26 MTs/Pallet | 16 pallets | 20.16 MTs | 20 DC |

Applications of rubber natural SVR 3L products

SVR 3L (also internationally traded as TSR 3L) is widely used across industries that require clean, consistent, and high-performance natural rubber. Many international buyers specify TSR 3L rubber in their technical sourcing requirements.

1. Automotive & Tire Industry

Typical Uses:

Passenger, truck, motorcycle, and aircraft tires; engine mounts, seals, gaskets, vibration-dampening parts

Why SVR 3L:

Good durability, strong bonding, and reliable performance under load

2. Industrial Rubber Goods

Typical Uses:

Conveyor belts, hoses, diaphragms, tank linings, anti-slip mats

Why SVR 3L:

Good abrasion resistance, strength, and stability in demanding environments

3. Electrical & Cable

Typical Uses:

Cable insulation layers and protective sheathing

Why SVR 3L:

Stable physical properties and suitable moisture resistance for selected uses

4. Medical & Hygiene (Selected Uses)

Typical Uses:

Medical tubing, rubber stoppers, technical healthcare components

Why SVR 3L:

Clean grade with controlled impurities

Note: Gloves and dipping products typically use latex concentrate.

5. Footwear & Consumer Goods

Typical Uses:

Shoe soles, rubber mats, household molded items

Why SVR 3L:

Flexible, durable, and easy to process

6. Adhesives & Tapes

Typical Uses:

Adhesives, BOPP tape backing, bonding compounds

Why SVR 3L:

Consistent viscosity and good elasticity support stable adhesive performance

Why Source SVR 3L from a Vietnam Manufacturer and Supplier Like Ngoc Chau Natural Rubber?

Sourcing SVR 3L from a reliable Vietnam manufacturer and supplier helps buyers secure stable quality, competitive pricing, and professional export support.

Ngoc Chau Natural Rubber is a Vietnam-based natural rubber manufacturer and exporter supplying SVR 3L to global markets.

1. Proven Quality Standards

SVR 3L is produced under ISO 9001 & TCVN standards with controlled impurity levels, stable Mooney viscosity, and high PRI for consistent compounding.

2. Reliable Supply Capacity

Large-scale production capacity ensures stable output and support for long-term contracts.

3. Export Experience

Regular exports to Asia, CIS, and Middle East markets with repeat international buyers.

4. Quality Transparency

Batch-level COA, standardized laboratory testing, and detailed loading reports support quality verification.

5. Efficient Logistics & Flexible Packing

Flexible bale sizes, pallet options, and global shipping terms (FOB, CIF, CNF) support different buyer needs.

1. What is the difference between SVR 3L and TSR 3L?

SVR 3L and TSR 3L refer to the same technically specified natural rubber grade. “SVR” is the Vietnam classification (Standard Vietnamese Rubber), while “TSR” is the international term (Technically Specified Rubber). In global trade, buyers often use both names interchangeably.

2. What industries commonly use SVR 3L rubber?

SVR 3L is widely used in tire manufacturing, industrial rubber goods, automotive components, adhesives, and selected cable and consumer applications. It is preferred where clean rubber, stable viscosity, and reliable mechanical properties are required.

3. Why is Mooney viscosity important when choosing SVR 3L?

Mooney viscosity indicates how the rubber behaves during processing. Stable Mooney values help manufacturers achieve consistent mixing, extrusion, and molding results, reducing defects and improving production efficiency.

4. How is SVR 3L packaged for export?

SVR 3L is typically packed in 33.33 kg or 35 kg bales, with options for palletized loading. Packaging is designed for safe sea transport, easy handling at factories, and optimized container weight. Export shipments usually include COA and required trade documents.

5. How do buyers ensure consistent SVR 3L quality between shipments?

Consistent quality is ensured through standardized production, laboratory testing, and batch-level Certificates of Analysis (COA). Reputable suppliers follow TCVN/ISO testing methods and maintain routine quality control to ensure stable specifications.

6. Is TSR 3L the same as SVR 3L?

Yes. TSR 3L and SVR 3L refer to technically specified natural rubber with equivalent quality parameters. “SVR” is Vietnam’s classification system, while TSR 3L is the internationally used terminology in global trade.

Conclusion

SVR 3L (TSR 3L) remains a trusted natural rubber grade for manufacturers who require clean rubber, stable processing, and consistent quality. For international buyers evaluating Vietnam SVR 3L manufacturers and suppliers, key considerations include COA consistency, Mooney stability, and reliable packaging standards.

With standardized production, strict quality control, and export experience, Ngoc Chau Natural Rubber supports global buyers with dependable SVR 3L supply and professional service.

If you are looking for a reliable Vietnam supplier of SVR 3L natural rubber, our team is ready to support your sourcing needs.

📞 Hotline / Mobile: +84 762 798 888

✉️ Email: info@ngocchausupplier.com

🌐 Website: www.ngocchausupplier.com

Ms Evan

Ms Evan