Contents

- 1 What is the definition of SVR 20 rubber?

- 2 Outstanding features of natural rubber SVR 20

- 3 Detailed review of the main technical parameters of the SVR 20

- 4 Method of packaging and wrapping rubber products svr 20

- 5 Top applications of SVR 20 rubber in global manufacturing

- 6 Why should you choose to buy SVR 20 products at Ngoc Chau?

- 7 FAQ – Everything you need to know about SVR 20 rubber

- 8 Conclusion

SVR 20 is a widely used natural rubber, appreciated for its balance of performance, uniformity and cost-effectiveness in the production of tires, footwear and industrial products. With stable Mooney viscosity, good processing characteristics and reliable quality, it is the preferred choice for manufacturers looking for solutions. At Ngoc Chau Natural Rubber, we ensure compliance with international standards, providing sustainable competitive prices to our partners.

What is the definition of SVR 20 rubber?

SVR 20 (Standard Vietnam Rubber) is a technically specified grade of natural rubber manufactured in Vietnam, commonly referred to as block rubber or crumb rubber. It is mainly sourced from secondary latex materials such as cup lumps, which imparts a harder and less flexible character to the product.

With an impurity level capped at 0.16% and a minimum Plasticity Retention Index (PRI) of 40, SVR 20 fully complies with international technical standards. Renowned for its durability, abrasion resistance, and consistent processing performance, Standard Vietnam Rubber 20 is extensively employed in tire production as well as in the manufacture of anti-vibration and shock-absorbing components.

Outstanding features of natural rubber SVR 20

As a versatile grade of natural rubber, SVR 20 is renowned for its technical stability and dependable performance across a broad spectrum of industrial applications. The attributes below illustrate why it remains a preferred choice among global manufacturers:

- Exceptional Durability: Although sourced from secondary latex, SVR 20 demonstrates remarkable longevity, enabling it to withstand demanding industrial environments.

- Superior Wear Resistance: Its outstanding resistance to abrasion is crucial for tire treads, which must endure constant and intensive friction.

- Elasticity and Resilience: With excellent rebound properties, SVR 20 is highly effective in products subject to repeated deformation, such as engine mounts and vibration dampers.

- Enhanced Hardness: Processing from secondary latex imparts greater hardness, ensuring consistent reliability in heavy-duty applications.

- Low Impurity Content & High PRI: With a maximum dirt content of 0.16% and a Plasticity Retention Index of 40 or higher, SVR 20 maintains long-term flexibility and strong to oxidative degradation.

- Impact Resistance: Its ability to absorb substantial shocks offers a significant advantage in manufacturing load-bearing components and tires.

- Cost Efficiency: By combining high performance with economic value, SVR 20 provides industries with a practical and cost-effective natural rubber solution.

Detailed review of the main technical parameters of the SVR 20

The performance of SVR 20 is underpinned by well-defined technical specifications, ensuring consistency, quality assurance, and suitability for a wide range of applications.

| Property | Test Result | Test Method (TCVN / ISO) |

| Dirt (retained on 45 μm sieve), % | 0.019 | TCVN 6089:2016 (ISO 249:2016) |

| Ash, % | 0.46 | TCVN 6087:2010 (ISO 247-1:2018) |

| Volatile Matter, % | 0.33 | TCVN 6088-1:2014 (ISO 248-1:2018) |

| Nitrogen, % | 0.24 | TCVN 6091:2016 (ISO 1656:2019) |

| Initial Wallace Plasticity (Po) | 45.1 | TCVN 8493:2010 (ISO 2007:2018) |

| Plasticity Retention Index (PRI), % | 53 | TCVN 8494:2020 (ISO 2930:2017) |

| Lovibond Colour | — | TCVN 6093:2013 (ISO 4660:2011) |

| Mooney Viscosity ML (1+4) at 100°C | — | TCVN 6090-1:2015 (ISO 289-1:2015) |

| Rheometric Cure (160°C, 100 cpm, ACS) | — | TCVN 12010:2017 (ISO 6502:2016) |

| Torque Min / Max (dNm) | — | — |

| Scorch Time (ts1, m:s) | — | — |

| Optimum Cure Time (t90, m:s) | — | — |

✅ All analyses of the submitted samples were conducted in compliance with Vietnamese Standard TCVN 3769:2016, in alignment with ISO 2000:2014.

Method of packaging and wrapping rubber products svr 20

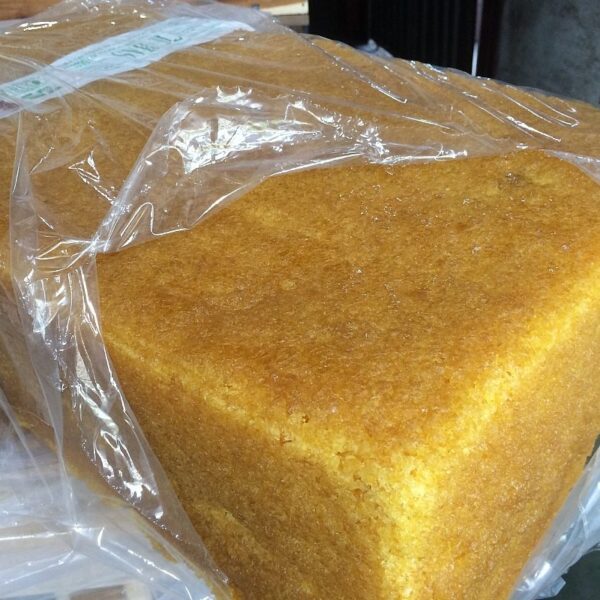

To meet international standards of preservation and transportation, SVR 20 is packaged under strict regulations, ensuring safety, cleanliness, and convenience for customers throughout the logistics process. Each bale is compressed into blocks of 33.33 kg or 35 kg, securely wrapped in PE bags, and shipped in 20-foot containers.

BALE:

| Quantity per Unit | Total Units | Container Type | Total Weight (MTs) |

| 33.33 kgs/Bale | 600 – 630 bales | 20 DC | 20 – 21 MTs |

| 35 kgs/Bale | 600 – 630 bales | 20 DC | 21 – 22.05 MTs |

PALLET:

| Quantity per Unit | Total Units | Container Type | Total Weight (MTs) |

| 33.33 kgs/Bale; 36 Bales / 1.2 MTs / Pallet | 16 pallets | 20 DC | 19.2 MTs |

| 35 kgs/Bale; 36 Bales / 1.26 MTs / Pallet | 16 pallets | 20 DC | 20.16 MTs |

Top applications of SVR 20 rubber in global manufacturing

As one of the most widely adopted grades of rubber, SVR 20 has become indispensable in global manufacturing. Produced from secondary latex, it combines durability, elasticity, hardness, and cost efficiency, making it suitable for a diverse range of applications. Below are the leading applications of SVR in industries.

1. Tyre & Tube Manufacturing

With its superior abrasion resistance and impact absorption, SVR 20 rubber is a key material in the production of bicycle, motorcycle and car tyres and tubes. Its durability ensures longer tread life, while its resilience supports both light and heavy duty two-wheelers.

2. Automotive Components & Spare Parts

The elasticity and resilience of SVR 20 make it ideal for shock absorbing components such as engine mounts, bushings and shock absorbers. In buses and coaches, it is also used for a wide range of rubber fittings and seals, providing safety, comfort and long life.

3. Heavy Industrial Goods

The hardness achieved through secondary latex processing makes SVR 20 suitable for demanding applications such as conveyor belts, gaskets, hoses and seals. Its ability to withstand heavy loads and repeated deformations ensures stable performance under harsh industrial conditions.

4. Footwear & Consumer Products

Due to its abrasion resistance and cost-effectiveness, SVR 20 is widely used in the production of waterproof shoe soles and footwear. In addition, its elasticity makes it suitable for everyday rubber products such as toys, inflatables and protective gear.

5. Shock Absorption & Vibration Control

With its high impact resistance, SVR 20 is used in products that are subject to strong impacts and heavy loads, including anti-vibration pads, railway components and industrial floors. This property ensures safety and durability in critical infrastructure and transportation systems.

Why should you choose to buy SVR 20 products at Ngoc Chau?

Choosing SVR 20 Vietnam from Ngoc Chau Natural Rubber means cooperating with a reputable supplier who puts quality, reliability and long-term value first. Our quality products are manufactured according to strict TCVN/ISO standards, ensuring extremely low impurity content, high Plasticity Retention Index (PRI) and consistent performance across all applications.

- Certified Quality: Every batch is rigorously tested and certified to guarantee compliance with international technical standards.

- Stable Supply: Backed by sustainable sourcing and modern processing facilities, we provide reliable volumes with punctual delivery.

- Competitive Pricing: We deliver cost-effective solutions without compromising quality, enabling partners to maximize efficiency.

- Versatile Applications: Our SVR 20 is ideally suited for tire production, automotive components, industrial goods, footwear, and consumer products.

- Global Recognition: Exported to many international markets, Ngoc Chau is trusted as a dependent partner in the natural rubber industry.

- Dedicated Service: Our professional team offers transparent communication, flexible logistics, and long-term customer support.

✅ With Ngoc Chau Natural Rubber, you gain not only high-performance SVR 20 but also a reliable business partner committed to your success.

FAQ – Everything you need to know about SVR 20 rubber

To help buyers and manufacturers better understand this essential rubber grade, we have compiled answers to the most frequently asked questions about Standard Rubber 20 Vietnam .

How does SVR 20 compare with other rubber grades?

Compared to higher-purity grades such as SVR 3L, S V R 20 has a slightly higher impurity level but delivers excellent hardness, resilience, and cost efficiency. This makes it more suitable for heavy-duty and industrial applications where affordability and strength are equally important.

Does SVR 20 meet international safety standards?

Yes. Ngoc Chau’s SVR 20 is rigorously tested in accordance with TCVN/ISO standards, guaranteeing full compliance with international specifications demanded by global buyers.

What are the shelf-life and usability of SVR 20?

When kept under appropriate storage conditions, SVR 20 retains its stability for 12 months or longer, ensuring consistent performance and dependable usability in industrial manufacturing.

Conclusion

SVR 20 is a dependable and versatile grade of natural rubber, prized for its durability, elasticity, and cost efficiency. At Ngoc Chau Natural Rubber, we guarantee strict TCVN/ISO compliance, low impurity levels, and reliable supply—offering not only premium material but also a long-term partnership you can trust.

Contact Ngoc Chau Natural Rubber Vietnam

Address: Lexington Building, No. 67 Mai Chi Tho Street, An Phu ward, Thu Duc City, Ho Chi Minh City

Hotline: +84 76 279 8888

Mobi: +84 76 279 8888

Email: info@ngocchausupplier.com

Ms Evan

Ms Evan