Contents

- 1 What is SVR 10 Natural Rubber?

- 2 Key Features of SVR 10 Natural Rubber

- 3 Quality Control Parameters Of SVR 10

- 4 SVR 10 transportation specifications

- 5 The Production Process of SVR 10 Natural Rubber

- 6 Applications of SVR 10 Natural Rubber

- 7 Why Choose Ngoc Chau as Your SVR 10 Supplier?

- 8 Conclusion

- 9 FAQ – SVR 10 Natural Rubber

What is SVR 10 Natural Rubber?

SVR 10, also internationally known as TSR 10 (Technically Specified Rubber 10), is one of the most widely used natural rubber grades in Vietnam, meeting high industry standards for durability, elasticity, and abrasion resistance. Thanks to its versatility, SVR 10 is an essential material in various sectors, including tire manufacturing, conveyor belts, and technical rubber products.

Vietnam, being one of the largest producers of natural rubber, ensures a stable supply of SVR 10 for both domestic and international markets. Ngoc Chau Natural Rubber stands out as a trusted Vietnam natural rubber supplier, providing high-quality SVR 10 that meets global standards and strict industrial requirements.

Key Features of SVR 10 Natural Rubber

Moderate Quality Level

SVR 10 features a medium Mooney viscosity (45–65 MU), positioning it as a mid-grade rubber. Compared to SVR 20 (lower grade with higher impurities) and SVR 3L (premium grade with superior purity and light color), SVR 10 offers a balanced option between performance and cost.

Good Abrasion Resistance

This grade provides solid wear and tear resistance, making it reliable for applications involving heavy loads and constant friction, such as tires and industrial components.

Reliable Elasticity

SVR 10 maintains consistent elasticity and tensile strength, ensuring durability across a wide range of products.

Cost-Effective Choice

As a mid-quality grade, SVR 10 delivers competitive pricing, helping manufacturers optimize production costs while maintaining dependable performance.

Easy Processing

Its stable characteristics make SVR 10 easy to process and blend. It is widely used as a versatile raw material in industries that require both quality and cost-efficiency.

Quality Control Parameters Of SVR 10

According to the Vietnamese Standard TCVN 3769:2016 base on ISO 2000:2014, the physical and chemical properties of natural rubber SVR 10 (equivalent to TSR 10 in many international specifications) are specified as follows:

-

Dirt content (through sieve): not more than 0.08% by weight

-

Ash content: not more than 0.60% by weight

-

Nitrogen content: not more than 0.60% by weight

-

Volatile matter: not more than 0.80% by weight

-

Initial Plasticity (P₀): not less than 30

-

Plasticity Retention Index (PRI): not less than 50

SVR 10 transportation specifications

SVR 10 is usually packaged in 4 main ways, depending on usage and transportation needs:

| Packaging Type | Quantity per Unit | Total Units | Total Weight (MTs) | Container Type |

| BALE | 33.33 kgs/Bale | 600 to 630 bales | 20 to 21 MTs | 20 DC |

| 35 kgs/Bale | 600 to 630 bales | 21 to 22.05 MTs | 20 DC | |

| PALLET | 33.33 kgs/Bale; 36 Bales/1.2MTs/Pallet | 16 pallets | 19.2 MTs | 20 DC |

| 35 kgs/Bale; 36 Bales/1.26MTs/Pallet | 16 pallets | 20.16 MTs | 20 DC |

The Production Process of SVR 10 Natural Rubber

Step 1 – Field Coagulum Collection & Pre-Cleaning

Fresh field coagulum is collected from plantations and carefully pre-cleaned to remove dirt and impurities, ensuring consistency for further processing.

Step 2 – Maturation

The raw materials undergo a controlled maturation period, allowing natural chemical stabilization. This step is essential for high-quality SVR 10 rubber production.

Step 3 – Cutting, Hammer Milling & Shredding

The matured coagulum is blended and processed through slab cutters, hammer mills, and shredders, producing uniform particles ready for drying.

Step 4 – Drying & Baling

The processed rubber is dried in hot-air chambers at controlled temperatures (≈110–120°C) to reduce volatile matter and moisture. Finally, the rubber is pressed into bales, meeting Vietnam natural rubber process standards (ISO/TCVN certified).

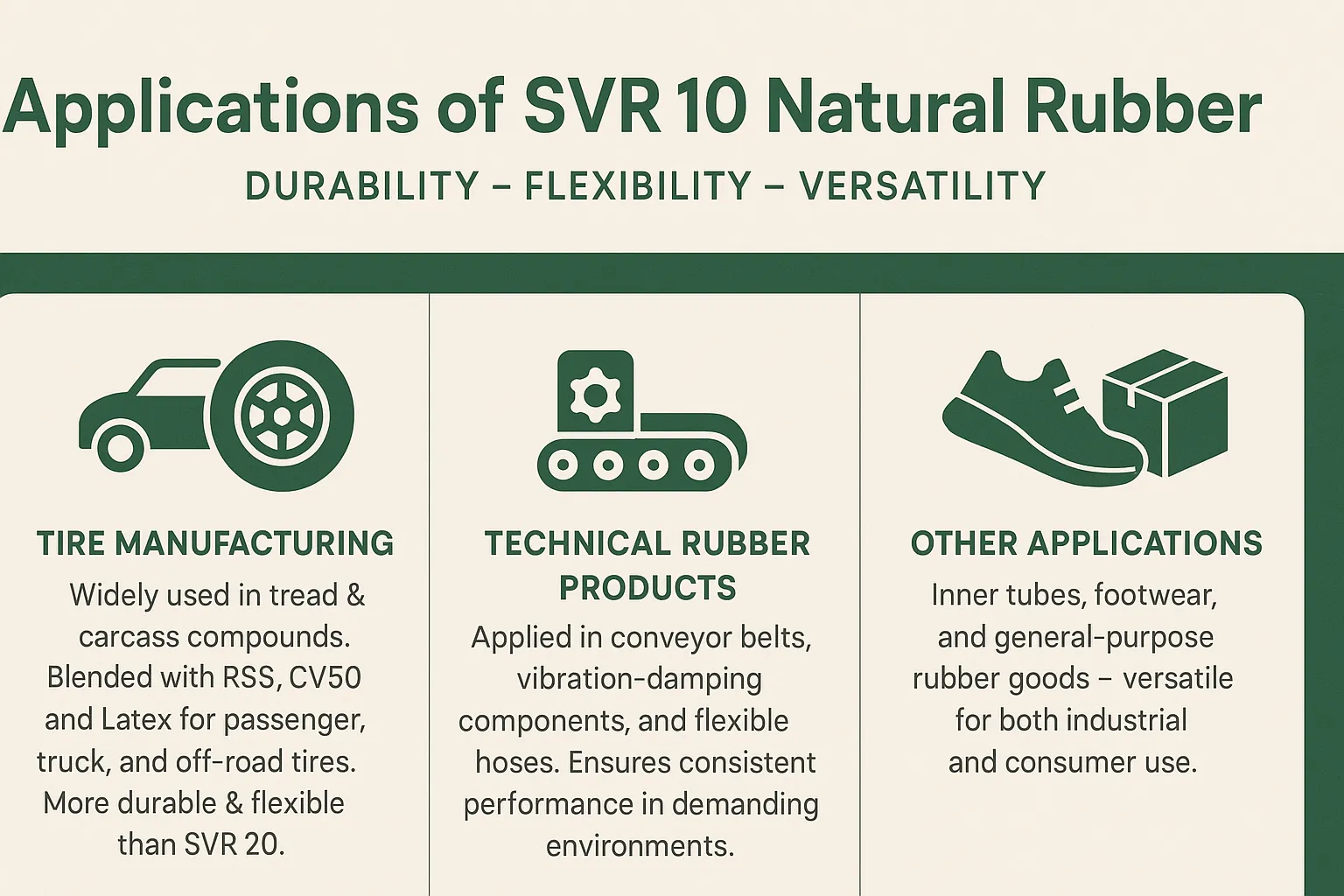

Applications of SVR 10 Natural Rubber

Tire Manufacturing

SVR 10 is widely used in tire production, often blended with lower-grade RSS, CV50, and Latex. Thanks to its balance of elasticity and abrasion resistance, it is suitable for tread and carcass compounds in passenger car, truck, and off-road tires. Compared to SVR 20, SVR 10 provides better durability and flexibility, making it a preferred choice for higher-performance tire formulations.

Technical Rubber Products

As one of the versatile industrial rubber products, SVR 10 is applied in the production of conveyor belts, vibration-damping components, and flexible hoses. Its stable processing properties ensure consistent performance in demanding industrial environments.

Other Applications

Beyond tires and technical goods, SVR 10 is also utilized in the manufacturing of inner tubes, footwear, and general-purpose rubber products. These broad SVR 10 applications highlight its importance in diverse Vietnam natural rubber uses, meeting both industrial and consumer requirements.

Why Choose Ngoc Chau as Your SVR 10 Supplier?

Ngoc Chau Natural Rubber is a certified SVR 10 manufacturer and exported in Vietnam, delivering consistent quality, stable supply, and competitive commercial terms for global industrial buyers.

MOQ: 1 x 20DC | COA per batch | FOB/CIF global shipment

Quality & International Certifications

SVR 10 complies with ISO/TCVN export standards, ensuring controlled viscosity, low impurity levels and long-term mechanical performance in tire, conveyor belt, and molded rubber applications.

Included:

-

COA (per shipment)

-

TDS & lab test results

-

Export documents: C/O, MSDS, PHYTO (where applicable)

Stable Mooney for Consistent Processing

Controlled Mooney index provides predictable curing, reduced defects, and optimized high-volume compounding.

Benefits:

-

Reliable for tire & conveyor production

-

Batch-to-batch uniformity

Competitive Export Pricing

Commercial pricing programs designed for global procurement teams with long-term capacity planning.

Key advantages:

-

Stable annual pricing

-

FOB/CIF competitive rates

-

Seasonal forecast on request

Reliable Lead Time & Port Logistics

Shipment is coordinated through major Vietnam terminals (Cai Mep & HCMC) to secure punctual delivery even in peak rubber seasons.

Standard lead time: 7–14 days

Support: dedicated export team for document handling

Export Packaging (Bale & Pallet Options)

Ngoc Chau offers export-grade bale and pallet formats engineered for secure stacking and maximum 20DC loading efficiency. Packaging is compatible with both clamp and forklift handling, ensuring clean delivery from factory to destination port.

Key Advantages:

✔ Reduced contamination & damage risk

✔ Optimized 20–21 MT loading per 20DC

✔ Clamp/forklift unloading compatibility

✔ COA & loading photos provided

✔ Optional fumigation & SGS inspection

COA & Samples for Factory Validation

Pre-shipment samples and COA help verify compatibility before full loading or blend testing (SVR 10 vs SVR 3L).

Available:

-

COA per container

-

Pre-shipment QC photos/video

-

Lab parameter comparison support

SVR 10 Export Support & Global Availability

Ngoc Chau maintains continuous export capacity with flexible shipment scheduling to Asia, Middle East, Africa, and Europe, supported by responsive logistics assistance and documentation accuracy.

Conclusion

SVR 10 is a mid-grade natural rubber that offers the perfect balance of quality, durability, processability, and cost-efficiency. As a trusted SVR 10 Vietnam supplier, Ngoc Chau Natural Rubber provides products that meet strict international standards.

Compared to SVR 20, SVR 10 delivers better elasticity and durability, while remaining more cost-efficient than SVR 3L, making it an optimal choice for tire manufacturing and a wide range of industrial applications.

At Ngoc Chau Natural Rubber, we guarantee consistent supply, competitive pricing, and technical support.

Contact us today for samples and quotations to experience the value of working with a reliable partner in the SVR 10 natural rubber market.

📞 Hotline / Mobile: +84 762 798 888

✉️ Email: info@ngocchausupplier.com

🌐 Website: www.ngocchausupplier.com

FAQ – SVR 10 Natural Rubber

1. What is SVR 10 natural rubber?

SVR 10 is a mid-grade Vietnam natural rubber produced mainly from field coagulum. It delivers a balance of quality, durability, and cost-efficiency, making it suitable for tire and industrial applications.

2. What are the key properties of SVR 10?

SVR 10 has medium Mooney viscosity (45–65 MU), strong abrasion resistance, reliable elasticity, and easy processability. These SVR 10 natural rubber properties make it a versatile material for manufacturers.

3. How is SVR 10 different from other rubber grades?

-

Compared to SVR 20, SVR 10 offers better elasticity and durability.

-

Compared to SVR 3L, it is more cost-efficient, though with lower purity.

4. What are the main applications of SVR 10?

SVR 10 is widely used in tire production (tread and carcass compounds), conveyor belts, hoses, anti-vibration parts, inner tubes, and footwear.

5. How is SVR 10 packaged for export?

It is packed in 33.33 kg or 35 kg bales, wrapped in PE film, and stacked on pallets. A 20’ DC container typically loads 19.2 MT (palletized) or 21.6 MT (non-palletized).

Ms Evan

Ms Evan