Contents

- 1 Introduction to RSS 3 Natural Rubber

- 2 Key Characteristics of RSS 3 Natural Rubber

- 3 Quality Control Parameters And Transportation Specifications of RSS 3 Natural Rubber

- 4 Manufacturing Process of RSS 3 (Ribbed Smoked Sheet 3)

- 5 Applications of RSS 3

- 6 Why Choose RSS 3 from Ngoc Chau Natural Rubber?

- 7 Conclusion

- 8 📌 FAQ – RSS 3 Natural Rubber

Introduction to RSS 3 Natural Rubber

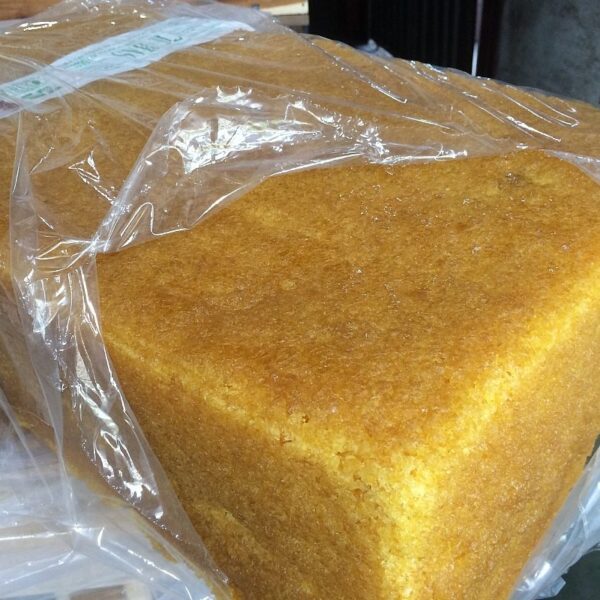

Ribbed Smoked Sheet 3 (RSS 3) is a premium grade of natural rubber produced through the coagulation of latex, followed by rolling, drying, and smoking to create ribbed sheets with excellent durability and elasticity. Known for its high tensile strength, abrasion resistance, and consistent quality, RSS 3 is widely used in tire manufacturing (especially truck, bus, and passenger car tires), as well as in industrial products such as hoses, footwear, and shock-absorbing components.

As a leading supplier from Vietnam, Ngoc Chau Natural Rubber delivers RSS 3 that meets international standards, ensuring stable performance, competitive pricing, and a reliable supply for global partners in the automotive and rubber industries.

Key Characteristics of RSS 3 Natural Rubber

1. Exceptional Strength and Reliability

RSS 3 is recognized as a premium grade of natural rubber, valued for its high tensile strength, excellent abrasion resistance, and outstanding elasticity. These qualities make it a dependable material for industries requiring durable and high-performance rubber.

2. Traditional yet Refined Processing

This grade is produced through a meticulous process: fresh latex is coagulated, rolled into ribbed sheets, and then carefully dried and smoke-cured. The smoking stage not only enhances durability but also imparts the distinctive color and aroma associated with ribbed smoked sheets.

3. Quality Grading and Classification

The “3” designation indicates a specific international grading standard. While minor blemishes or small specks are permissible, RSS 3 must remain clean, structurally sound, and evenly smoked to meet export requirements and customer expectations.

4. Balanced Quality and Cost Efficiency

Combining consistent performance with competitive pricing, RSS 3 achieves an ideal balance of quality and affordability. Its versatility and reliability make it one of the most widely traded and sought-after natural rubber grades in global markets.

Quality Control Parameters And Transportation Specifications of RSS 3 Natural Rubber

1. Quality Control Parameters

According to the Vietnamese Standard TCVN 3769:2016 base on ISO 2000:2014, the physical and chemical properties of natural rubber RSS 3 are specified as follows:

| Property | Test results | Test Methods |

| Dirt content retained on sieve (% by weight) | 0.007 | TCVN 6089:2016 (ISO 249:2016) |

| Ash content (% by weight) | 0.2 | TCVN 6087:2010 (ISO 247-1:2018) |

| Volatile matter content (% by weight) | 0.44 | TCVN 6088-1:2014 (ISO 248-1:2018) |

| Nitrogen content (% by weight) | 0.37 | TCVN 6091:2016 (ISO 1656:2019) |

| Initial Wallace Plasticity (P₀) | 47.3 | TCVN 8493:2010 (ISO 2007:2018) |

| Plasticity Retention Index (PRI) | 88 | TCVN 8494:2020 (ISO 2930:2017) |

| Mooney Viscosity | 89.2 | TCVN 6090-1:2015 (ISO 289-1:2015) |

2. RSS 3 transportation specifications

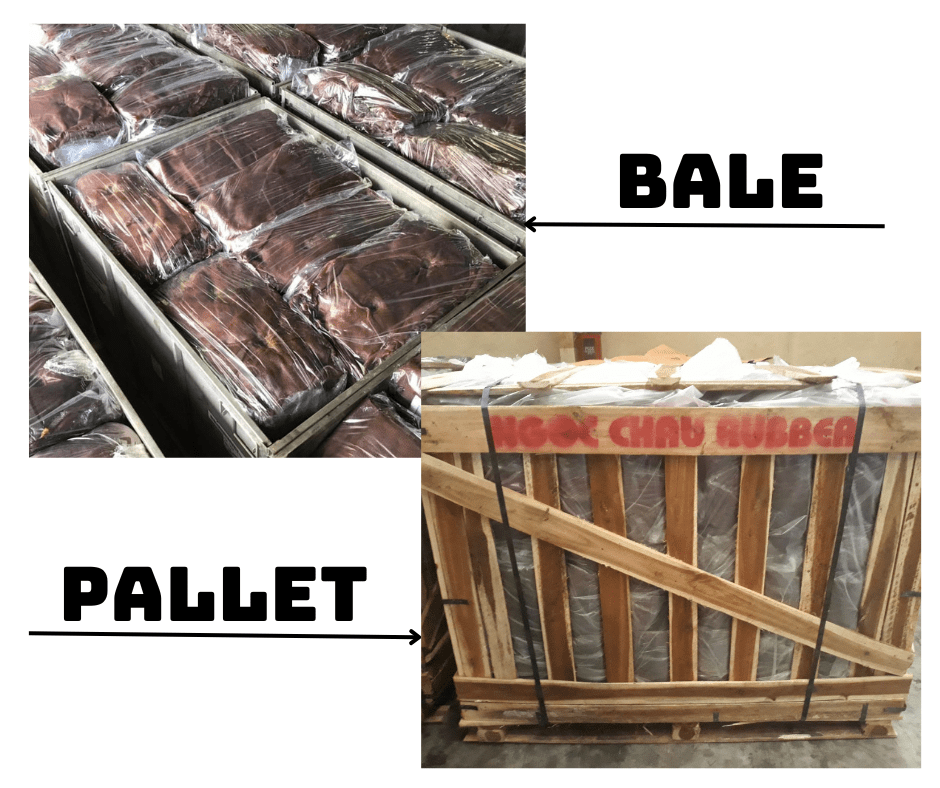

RSS 3 is usually packaged in 4 main ways, depending on usage and transportation needs:

| Packaging Type | Quantity per Unit | Total Units | Total Weight (MTs) | Container Type |

| BALE | 33.33 kgs/Bale | 600 to 630 bales | 20 to 21 MTs | 20 DC |

| 35 kgs/Bale | 600 to 630 bales | 21 to 22.05 MTs | 20 DC | |

| PALLET | 33.33 kgs/Bale; 36 Bales/1.2MTs/Pallet | 16 pallets | 19.2 MTs | 20 DC |

| 35 kgs/Bale; 36 Bales/1.26MTs/Pallet | 16 pallets | 20.16 MTs | 20 DC |

Manufacturing Process of RSS 3 (Ribbed Smoked Sheet 3)

RSS 3 natural rubber is produced through a traditional smoke-curing method designed to ensure durability, consistency, and compliance with international standards. The main steps in the production process include:

-

Latex Collection – Fresh latex is tapped from Hevea brasiliensis trees early in the morning to maintain purity and reduce impurities.

-

Coagulation – The latex is treated with formic acid or similar agents, causing rubber particles to solidify and separate from water.

-

Sheeting & Rolling – Coagulated blocks are pressed into thin ribbed sheets that improve drying efficiency, prevent sticking, and simplify handling.

-

Drying & Smoking – Sheets are smoke-cured in drying chambers, where controlled heat removes moisture, prevents mold, and gives RSS its distinctive brown color.

-

Quality Grading – Each sheet is visually inspected following international grading standards. RSS 3 permits slight blemishes but guarantees high elasticity, strength, and cleanliness.

Applications of RSS 3

RSS 3 natural rubber is a versatile industrial material renowned for its durability, elasticity, and resistance to wear. Its wide range of applications spans multiple sectors:

- Tire Manufacturing – Serving as a core raw material for passenger cars, trucks, and off-road vehicles, RSS 3 is essential in producing treads and carcasses. Its high tensile strength and abrasion resistance ensure safety, performance, and long service life for tires.

- Industrial Products – Widely used in manufacturing rubber hoses, conveyor belts, gaskets, and shock absorbers, RSS 3 provides outstanding stability and resilience, even under demanding operational conditions.

- Footwear & Consumer Goods – From durable shoe soles to waterproof rubber products, RSS 3 enhances flexibility, elasticity, and water resistance, making it a reliable choice for everyday consumer applications.

Why Choose RSS 3 from Ngoc Chau Natural Rubber?

1. Superior Quality & Performance

Our RSS 3 is produced through rigorous processing and strict quality control, ensuring high tensile strength, low dirt content, and optimal elasticity. The rubber sheets are uniformly smoked and meticulously inspected to meet international standards.

2. Consistent Supply & Competitive Pricing

With a robust production capacity, we guarantee a stable and continuous supply of RSS 3 at competitive prices. Our efficient production and cost management enable us to offer premium rubber at the best market rates, fostering long-term partnerships.

3. Comprehensive Customer Support

We provide expert guidance on rubber selection and application, ensuring our customers receive the best solutions for their needs. Our support includes detailed technical documentation such as COA, MSDS, TDS, and C/O for seamless transactions and regulatory compliance.

4. Advanced Processing & Sustainability

Our state-of-the-art facilities ensure uniform quality, high purity, and environmental responsibility. We employ sustainable rubber processing methods that enhance efficiency while minimizing ecological impact.

5. Reliable Logistics & Flexible Shipping

We offer fast and secure shipping worldwide, ensuring timely delivery through optimized packaging and logistics solutions. Our team works closely with clients to meet their specific storage and transportation requirements.

Conclusion

RSS 3 remains one of the most reliable and widely used grades of natural rubber, valued for its strength, elasticity, and cost efficiency.

At Ngoc Chau Natural Rubber, we deliver RSS 3 that meets international standards with strict quality control, sustainable processing, and flexible logistics — ensuring consistent supply and competitive pricing for global partners.

📩 Contact us today to explore reliable natural rubber solutions with Ngoc Chau.

📌 FAQ – RSS 3 Natural Rubber

Q1. What is RSS 3 natural rubber?

RSS 3 (Ribbed Smoked Sheet 3) is a grade of natural rubber made from coagulated latex, rolled into ribbed sheets, and smoke-cured for durability and elasticity.

Q2. What are the main properties of RSS 3?

It offers high tensile strength, abrasion resistance, elasticity, and low dirt content — ideal for demanding industrial use.

Q3. What is RSS 3 used for?

RSS 3 is widely applied in tire production, industrial goods (hoses, belts, gaskets), and consumer products like footwear.

Q4. How is RSS 3 packaged for export?

It is packed in bales (33.33–35 kg) or pallets, shipped in 20-foot containers with 19–22 MTs per load.

Q5. Why choose Ngoc Chau Natural Rubber for RSS 3?

Ngoc Chau ensures international-standard quality, stable supply, competitive pricing, and flexible global logistics.

Ms Evan

Ms Evan