Contents

Vietnam has emerged as a key global supplier of specialized latex products, particularly the HA 60% DRC grade used in premium tire manufacturing and medical glove production. With $4.4 billion annual revenue from deep-processed rubber exports, the country combines sustainable farming practices with advanced processing technologies to meet international quality demands.

Vietnam’s Latex DRC Production Profile

Controlled from even the collection of fresh field latex from small holders, concentrated it is pure and is one of the most clean raw materials in terms of rubber. Fresh field latex is preserved with added chemicals and centrifuged to obtain a concentrated latex of 60% DRC (dry rubber contents). Ammonia is added during the process to enhance the preservation, but depending on specific requirements of the customer, various degrees are added to the concentrated latex.

Latex rubber is known to have 3 main types: Latex HA, Latex MA, Latex LA

- Natural rubber Latex HA (High Ammonia) is a type of rubber with a high ammonia content, processed to ensure stability during storage and transportation. Thanks to the high ammonia concentration, Latex HA has the ability to prevent bacteria and mold, helping to maintain superior quality compared to low ammonia Latex (Latex LA). This product is widely used in many industries, especially the production of medical products, rubber gloves, adhesives and high-tech rubber products.

- Natural rubber Latex MA (Medium Ammonia) has an average ammonia content (0.3% – 0.6%), which helps balance stability and a lighter odor, and is often used in the production of household gloves, rubber mattresses, paints and ceramics.

- Natural rubber Latex LA (Low Ammonia) is a natural rubber with low ammonia content (≤ 0.3%), which helps reduce odor and is less irritating but requires preservatives to prevent bacteria and mold. Used in the production of medical gloves, balloons, condoms, glue and foam pads.

Origin Specifications

- Cultivated across 940,000 hectares of FSC-certified plantations in Southeast rubber belt regions

- Processed by ISO-certified facilities like Ngoc Chau Factory using cryogenic preservation techniques

- Characteristic carotenoid pigments (0.15-0.35 mg/g) create natural yellow hue in fresh latex

Quality Control Parameters

| Property | Test result | Limit | Test Methods |

| Total Solids Content %(m/m) | 61.58 | ≥ 61.00 | TCVN 6315:2015 (ISO 124:2014) |

| Dry Rubber Content %(m/m) | 60.20 | ≥ 60.00 | TCVN 4856:2007 (ISO 126:2005) |

| Non Rubber solids %(m/m) | 1.38 | ≤ 1.70 | – |

| Alkalinity/Latex Concentrate%(m/m) | 0.70 | ≥ 0.60 | TCVN 4857:2015 (ISO 125:2011) |

| Mechanical Stability Time (MST),s | 942 | ≥ 650 | TCVN 6316:2007 (ISO 125:2004) |

| Volatile Fatty Acid (VFA) | 0.029 | ≤ 0.06 | TCVN 6321:1997 (ISO 506:1992) |

| KOH number | 0.54 | ≤ 0.7 | TCVN 4856:2015 (ISO 127:2012) |

| pH Value | 10.63 | – | TCVN 4860:2015 (ISO 976:2013) |

| Coagulum content %(m/m) | 0.003 | ≤ 0.03 | TCVN 6317:2007 (ISO 706:2004) |

| Sludge content %(m/m) | 0.006 | ≤ 0.10 | TCVN 6320:2016 (ISO 2005:2014) |

| Copper content (mg/kg) | – | ≤ 8 | TCVN 6318:1997 (ISO 8053:1995) |

| Manganese content (mg/kg) | – | ≤ 8 | TCVN 6319:2007 (ISO 7780:1998) |

| Brookfield Viscosity (cP) | 93.5 | – | TCVN 4859:2013 (ISO 1652:2011) |

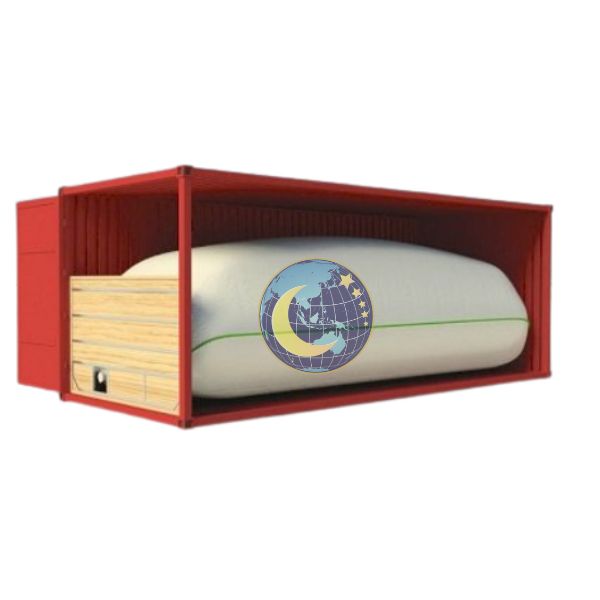

Natural rubber latex transportation specifications

Latex rubber is usually packaged in 4 main ways, depending on usage and transportation needs:

| Quality | Can | Drum | Flexibag | IBC Tank |

| Labels | Labels by Ngoc Chau | No logo printing, only product information printing | No logo printing, only product information printing | No logo printing, only product information printing |

| Documents | Full, no price and quantity adjustments | Full, no price and quantity adjustments | Full, no price and quantity adjustments | Full, no price and quantity adjustments |

| Preparation time for 1 container | 20-35 days | 10-15 days | 15-20 days | 15-20 days |

| Quantity | less than or equal to 100 tons | less than or equal to 100 tons | less than or equal to 100 tons | less than or equal to 100 tons |

| Vessel line | No special shipping time or shipping line required | No special shipping time or shipping line required | No special shipping time or shipping line required | No special shipping time or shipping line required |

| Packaging | Package in Jerry Can: 25kgs/can, 900 Cans, 22.5MTs/20DC |

Package in Black/Blue Steel Drum/Interior Coated Drum: 200kgs/drum; 80 or 98 Drums/16 or 19.6MTs/20DC.

Package in New Blue Steel Drum: 200-205kgs/drum

80 Drums/16.4MTs/20DC, with or without pallets

|

Package in Flexibag 20/21/21.5MTs/Flexibag |

Package in Recycled IBC

IBC Tank Exploision Proof: 960kgs/Tank, 20 Tanks/ 19.2 MTs/ 20DC Container

Package in Recycled IBC

IBC Plastic Tank: 960kgs/Tank, 20 Tanks/ 19.2 MTs/ 20DC Container

960kg/Recycled IBC Tank,

26 Tanks/24.96 MTs/container 40DC

|

Ms Evan

Ms Evan